Technology

The technology department is divided into sections: new product launches, technology, and construction. The department’s task is to develop processes for the production of new products with particular emphasis on forging and rolling technologies. Sections also deal with optimizing and improvement of processes used in production for bolts, screws, rivets, and bushings.

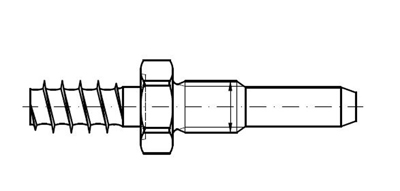

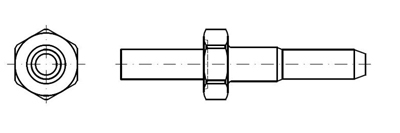

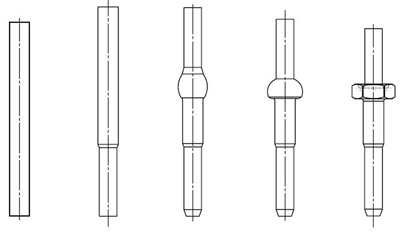

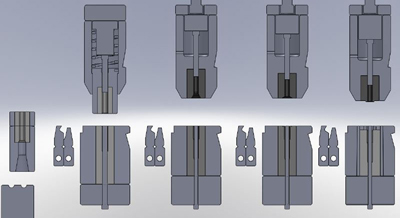

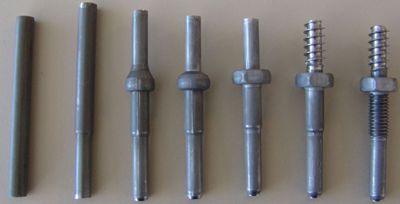

The cycle of work on the new product is presented on the example of a stud bolt (metric and plastic thread).

1. Stage of element design:

• selection of material grade depending on the required mechanical properties

• preparation of construction drawing

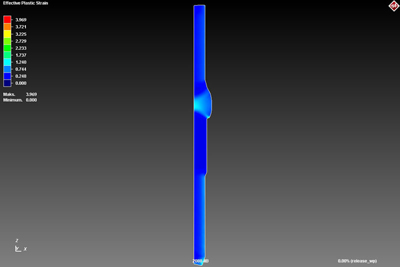

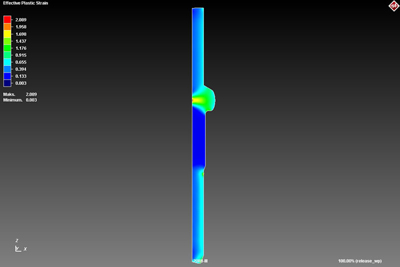

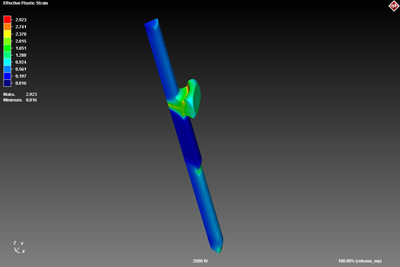

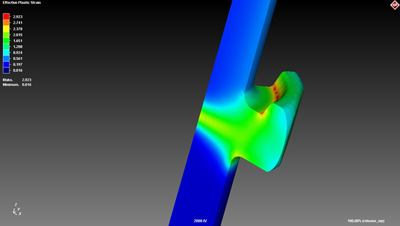

3. Development of forging technology on a multi-operation press and thread rolling.

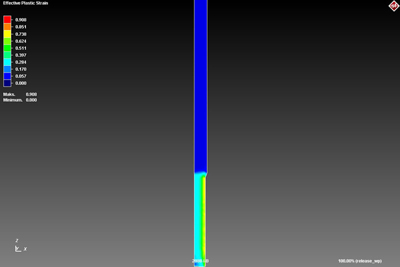

• development of the initial technological process of forging

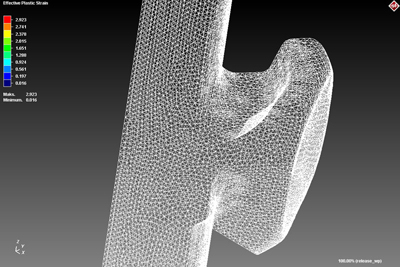

• numerical analysis (process simulation) of forging using the special program (Simufact 12.0) based on the FEM finite element method